Welche Umkehrosmosemembran wird zur Meerwasserentsalzung verwendet?

Eine große industrielle Meerwasserentsalzungsanlage verwendet Hohlfaser-Umkehrosmosemembranen mit einem vollständigen Vorbehandlungssystem. Nach drei Jahren Betrieb, regelmäßiger Reinigung und Wartung bleibt die Leistung der Membran stabil. Überwachungsdaten zufolge ersetzte das System nach vier Betriebsjahren eine Reihe von Umkehrosmosemembranen und stellte so die Qualität des entsalzten Wassers und die Systemeffizienz sicher.

Fall 3: KüstenresortEin Küstenresort nutzt flache Umkehrosmosemembranen zur Entsalzung von Meerwasser, um den Trinkwasserbedarf von Touristen zu decken. Da Meerwasser viele Schwebstoffe und organische Stoffe enthält, wird die Anlage zweimal im Jahr vollständig gereinigt. Nach dreijähriger Nutzung hat die Salzrückhalterate der Membran nachgelassen und muss ersetzt werden.Fazit zu den Arten von Umkehrosmosemembranen und Austauschzyklen

Umkehrosmosemembranen sind die Kernkomponenten von Meerwasserentsalzungsanlagen. Die Wahl des richtigen Membrantyps und eines angemessenen Austauschzyklus ist entscheidend für die Gewährleistung der Qualität des entsalzten Wassers und der Effizienz des Systembetriebs. Spiralgewickelte Membranen, Hohlfasermembranen und flache Umkehrosmosemembranen haben in verschiedenen Anwendungsszenarien ihre eigenen Vorteile und sollten entsprechend den spezifischen Umständen ausgewählt werden.

Durch eine wirksame Vorbehandlung, regelmäßige Wartung und Reinigung sowie rechtzeitige Überwachung und Tests kann die Lebensdauer der Umkehrosmosemembran verlängert werden, um den effizienten Betrieb der Meerwasserentsalzungsanlage sicherzustellen.

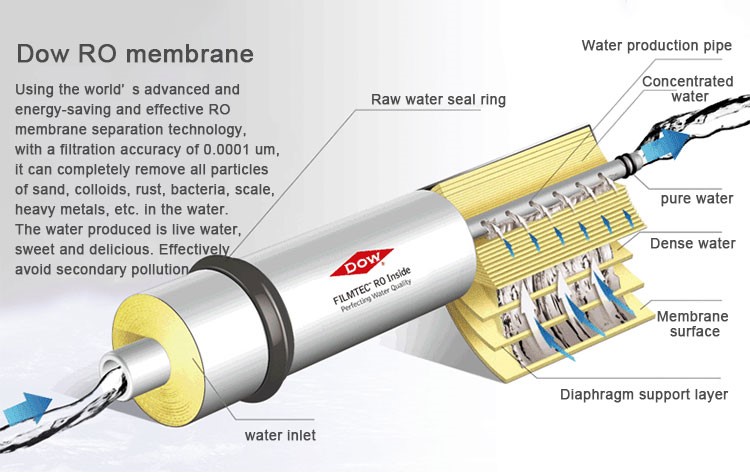

1. Water inlet: Seawater passes through the reverse osmosis membrane under the action of a high-pressure pump.

2. Filtration: Water molecules pass through the tiny pores on the membrane, while impurities such as salt, heavy metals, and microorganisms are retained.

3. Water production and concentrated water: The filtered pure water (produced water) enters the clean water storage tank, and the water with concentrated impurities (concentrated water) is discharged. The choice of reverse osmosis membrane directly affects the efficiency and water quality of the desalination system.

Which reverse osmosis membrane is used for seawater desalination?

Types of reverse osmosis membranes used in seawater desalination:

1. Spiral-wound reverse osmosis membrane,

2. Flat-plate reverse osmosis membrane,

3. Hollow fiber reverse osmosis membrane.

In the process of seawater desalination, the reverse osmosis membrane needs to have high salt resistance and anti-pollution ability. The following is a detailed introduction to these three commonly used types of reverse osmosis membranes:

1. Spiral-wound reverse osmosis membrane:

Spiral-wound reverse osmosis membrane is currently the most commonly used type of reverse osmosis membrane and is widely used in seawater desalination systems. It has a compact structure, large filtration area and high efficiency.

● Advantages: small space occupation, low energy consumption, good filtration effect; the membrane can be folded into a spiral shape, which increases the surface area of the membrane and improves the processing capacity.

● Disadvantages: high requirements for influent pretreatment, regular cleaning and maintenance are required.

2. Flat-plate reverse osmosis membrane:

Flat-plate reverse osmosis membrane is mainly used in small seawater desalination systems and has higher anti-pollution ability.

● Advantages: simple structure, easy maintenance and replacement; strong anti-pollution ability, suitable for seawater desalination with poor water quality.

● Disadvantages: Large floor space and limited processing capacity.

3. Hollow fiber reverse osmosis membrane:

Hollow fiber reverse osmosis membrane adopts hollow fiber structure, which has the characteristics of high strength and high flux, and is suitable for large-scale seawater desalination systems.

● Advantages: High filtration accuracy and strong processing capacity; the hollow fiber structure increases the strength of the membrane and is suitable for high-pressure environments.

● Disadvantages: Complex manufacturing process and high cost.

How often should you replace the reverse osmosis membrane?

The replacement cycle of the reverse osmosis membrane is an important factor in ensuring the efficient operation of the desalination system. The replacement cycle is affected by many factors, including the quality of the influent water, the operating pressure, and the degree of contamination of the reverse osmosis membrane.

1. Influent water quality:

Impurities, microorganisms and suspended matter in seawater can cause contamination and clogging of the reverse osmosis membrane. The worse the influent water quality, the faster the membrane is contaminated and needs to be replaced more frequently.

● Seawater: Usually contains high salt, microorganisms and organic matter, and is more seriously polluted.

● Pretreatment: Effective pretreatment (such as sand filtration, activated carbon filtration) can reduce the impurities entering the reverse osmosis membrane and increase the service life of the membrane.

2. Operating pressure:

Operating pressure is one of the key factors affecting the service life of the reverse osmosis membrane. High pressure will accelerate the wear and aging of the membrane and reduce the service life.

● High pressure: Increases the burden on the membrane and requires frequent inspection and maintenance.

● Appropriate pressure: The operating pressure should be set according to the design parameters of the membrane to avoid being too high or too low.

3. The degree of contamination of the reverse osmosis membrane:

The degree of contamination of the membrane directly affects its filtration effect and service life. Common types of contamination include:

● Biological contamination: Microorganisms grow and multiply on the surface of the membrane to form a biofilm.

● Chemical contamination: Chemical substances in the water react with the membrane material, resulting in a decrease in membrane performance.

● Physical contamination: Suspended matter and particulate matter block the membrane pores and affect water flow.

4. Recommended replacement cycle of reverse osmosis membrane:

Based on the above factors, the replacement cycle of reverse osmosis membrane is usually:

● Home or small system: Replace the reverse osmosis membrane about every 2-3 years, depending on the usage and water quality conditions.

● Industrial and large systems: Replace the reverse osmosis membrane about every 3-5 years, and regular performance testing and maintenance are required.

Maintenance and cleaning of reverse osmosis membrane

In order to extend the service life of the reverse osmosis membrane, in addition to regular replacement, effective maintenance and cleaning are also required.

1. Regular cleaning:

Regular cleaning of reverse osmosis membrane can remove pollutants on the membrane surface and maintain efficient operation. Cleaning methods mainly include chemical cleaning and physical cleaning.

● Chemical cleaning: Use special cleaning agents to remove biofilms, chemical pollutants and organic matter.

● Physical cleaning: Remove suspended matter and particulate matter on the membrane surface through backwashing or ultrasonic cleaning.

2. Monitoring and testing:

Regularly monitor the performance parameters of reverse osmosis membranes, such as flux, salt retention rate and pressure difference, to detect and deal with problems in a timely manner.

● Flux monitoring: A decrease in flux may mean that the membrane is contaminated or damaged, and it needs to be cleaned or replaced in time.

● Salt retention rate: A decrease in salt retention rate indicates that the membrane performance has decreased, and it needs to be cleaned or replaced.

● Pressure difference monitoring: An increase in pressure difference may be a signal that the membrane is blocked or contaminated, and it needs to be cleaned or replaced.

User case analysis

The following are several actual user cases to help understand the selection and replacement cycle of reverse osmosis membranes:

Case 1: Home desalination system

A family installed a small seawater desalination system using spiral wound reverse osmosis membranes. Because seawater contains a lot of organic matter and microorganisms, after one year of operation, the system found that the flux decreased significantly, and chemical and physical cleaning were required. After cleaning, the performance of the membrane was restored and the service life was extended. Finally, after two and a half years of use, a new reverse osmosis membrane was replaced.

Case 2: Industrial desalination plant

A large industrial seawater desalination plant uses hollow fiber reverse osmosis membranes with a complete pretreatment system. After three years of operation, regular cleaning and maintenance, the performance of the membrane remains stable. According to monitoring data, the system replaced a batch of reverse osmosis membranes after four years of operation, ensuring the desalinated water quality and system efficiency.

Case 3: Coastal Resort

A coastal resort uses flat reverse osmosis membranes to desalinate seawater to meet the drinking water needs of tourists. Since seawater contains a lot of suspended matter and organic matter, the system is fully cleaned twice a year. After three years of use, the salt retention rate of the membrane has decreased and needs to be replaced.

Conclusion on the types of reverse osmosis membranes and replacement cycles

Reverse osmosis membranes are the core components of seawater desalination systems. Choosing the right membrane type and a reasonable replacement cycle is crucial to ensuring desalinated water quality and system operation efficiency. Spiral wound, hollow fiber and flat reverse osmosis membranes have their own advantages in different application scenarios and should be selected according to specific circumstances.

Through effective pretreatment, regular maintenance and cleaning, and timely monitoring and testing, the service life of the reverse osmosis membrane can be extended to ensure the efficient operation of the seawater desalination system.

Fall 2: Industrielle Entsalzungsanlage