Was bedeuten 500 LPH in einem 500 LPH-Umkehrosmosegerät?

Eine Elektronikfertigungsanlage stellt extrem hohe Anforderungen an die Reinheit des Reinigungswassers und herkömmliche Wasseraufbereitungsmethoden können diese Anforderungen nur schwer erfüllen. Durch die Einführung von 500-LPH-Umkehrosmoseanlagen kann Reinigungswasser hohe Reinheitsstandards erfüllen und die Produktqualität erheblich verbessern. Gleichzeitig arbeiten die Geräte effizient und haben niedrige Wartungskosten, was dem Unternehmen hilft, die Produktionseffizienz zu verbessern und wirtschaftliche Vorteile zu erzielen.Fall 3: Landwirtschaftliche BewässerungEin moderner Bauernhof liegt in einem Salz-Alkali-Gebiet und das Bewässerungswasser hat einen hohen Salzgehalt, der das Pflanzenwachstum beeinträchtigt."500 LPH Umkehrosmoseanlage"Entfernt effektiv Salz und Schadstoffe aus dem Wasser, sorgt für hochwertiges Bewässerungswasser, verbessert den Ernteertrag und die Qualität und verbessert das Bodenmilieu.

Fazit zur 500 LPH Umkehrosmoseanlage

Die 500 LPH in der 500 LPH-Umkehrosmoseanlage bedeuten, dass die Anlage 500 Liter Wasser pro Stunde verarbeiten kann. Dieser Parameter ist ein wichtiger Indikator zur Beurteilung der Verarbeitungskapazität der Anlage. Umkehrosmosegeräte werden häufig in Haushalten, Gewerbe, Industrie und Landwirtschaft eingesetzt. Es kann Verunreinigungen und Schadstoffe im Wasser effektiv entfernen und hochwertiges, reines Wasser liefern.

Wenn Verbraucher Umkehrosmosegeräte kaufen und verwenden, müssen sie das geeignete Gerätemodell und die entsprechende Konfiguration entsprechend den tatsächlichen Bedürfnissen und Wasserqualitätsbedingungen auswählen, um einen effizienten Betrieb der Geräte und eine stabile Wasserversorgung sicherzustellen."Liters Per Hour", which means "liters per hour". Therefore, 500 LPH means that the reverse osmosis equipment can process 500 liters of water per hour. This label is usually used to describe the water production capacity or water treatment volume of the equipment, and is an important indicator for evaluating equipment performance and selecting suitable equipment.

What is the working principle of reverse osmosis equipment?

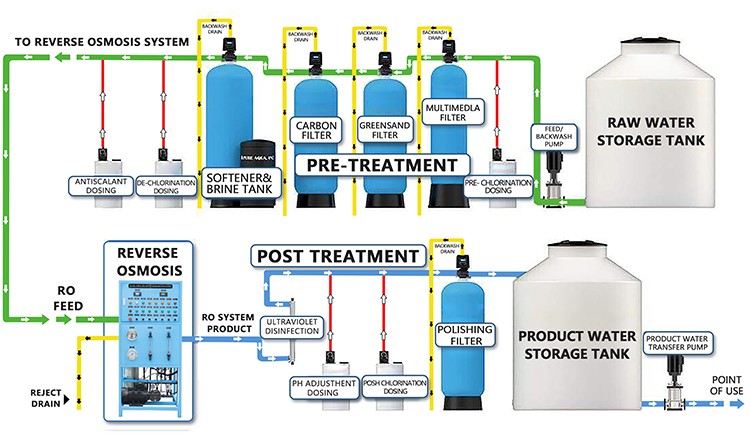

Before delving into the specific application of 500 LPH, first understand the working principle of reverse osmosis equipment. Reverse osmosis is a technology that uses a semipermeable membrane to separate solvents and solutes, and is widely used in water treatment. Its core principles are as follows:

1. Water inlet: Raw water (such as tap water, groundwater, seawater, etc.) enters the reverse osmosis system through a high-pressure pump.

2. Pretreatment: The raw water first passes through pretreatment steps such as filter elements and activated carbon to remove large particle impurities, suspended solids, residual chlorine, etc.

3. Reverse osmosis membrane: The pretreated water passes through a semipermeable membrane. Under high pressure, water molecules pass through the membrane, while impurities such as dissolved salts, organic matter, and heavy metals are retained on one side of the membrane.

4. Pure water and concentrated water: Pure water passing through the membrane enters the pure water storage tank, while the retained impurities form concentrated water and are discharged.

What are the uses of 500 LPH reverse osmosis equipment?

As the processing capacity of the equipment, 500 LPH has many practical significance and application value. For example: home and commercial use, industrial use, agricultural use, etc.

1. Home and commercial use:

In home and small commercial environments, 500 LPH reverse osmosis equipment is sufficient to meet the needs of daily drinking water and light industrial water. For example, a small or medium-sized restaurant or coffee shop may have a daily water demand of several hundred liters to one thousand liters. A 500 LPH device can provide sufficient pure water in a relatively short time to ensure the smooth operation of the business.

2. Industrial use:

In some light industries and small and medium-sized factories, 500 LPH reverse osmosis equipment can be used to treat cooling water, boiler water, cleaning water, etc. For example, an electronics manufacturing plant needs high-purity water to clean electronic components. A 500 LPH device can stably provide high-quality pure water to meet production requirements.

3. Agricultural use:

In the agricultural field, especially in modern agriculture, the quality of irrigation water directly affects the growth and yield of crops. A 500 LPH reverse osmosis device can provide farms with high-quality irrigation water, remove salt and harmful substances in the water, and improve the growth environment of crops.

Selection and configuration of reverse osmosis equipment

After understanding the significance of 500 LPH, other factors need to be considered when purchasing and configuring reverse osmosis equipment, such as raw water quality, usage scenarios, and operating costs.

1. Raw water quality:

The water quality of different water sources varies greatly. When selecting reverse osmosis equipment, it is necessary to make targeted designs based on the raw water quality. For example, the reverse osmosis membranes and system configurations required for treating groundwater and treating seawater are different. The more complex the raw water quality, the more pretreatment steps there are, and the corresponding costs will also increase.

2. Usage scenarios:

The usage scenarios of reverse osmosis equipment directly affect its configuration and installation. For example, reverse osmosis equipment used in households is usually small in size and easy to install, while industrial equipment needs to consider the equipment's floor space, energy consumption and maintenance costs.

3. Operating costs:

Operating costs are a key factor to consider when selecting reverse osmosis equipment. Including electricity costs, replacement costs of filter elements and reverse osmosis membranes, maintenance and cleaning costs, etc. The larger the equipment's processing capacity, the higher the operating cost, but it can also provide a larger water output, which needs to be weighed according to actual needs.

User experience and feedback of purchasing 500 LPH reverse osmosis equipment

After using 500 LPH reverse osmosis equipment, many users generally reported that it has high processing efficiency, excellent water quality and stable operation. For example, the owner of a medium-sized restaurant said that since installing a 500 LPH reverse osmosis device, the quality of kitchen water has improved significantly, the food tastes better, and customer satisfaction has also increased.

Another example is an electronics manufacturing plant. After using a 500 LPH reverse osmosis device, the purity of the cleaning water meets the requirements, the product quality is guaranteed, and the equipment is reliable and easy to maintain, which reduces production costs.

Maintenance and care of 500 LPH reverse osmosis equipment

The maintenance and care of reverse osmosis equipment is an important part of ensuring its long-term stable operation. Here are some key points:

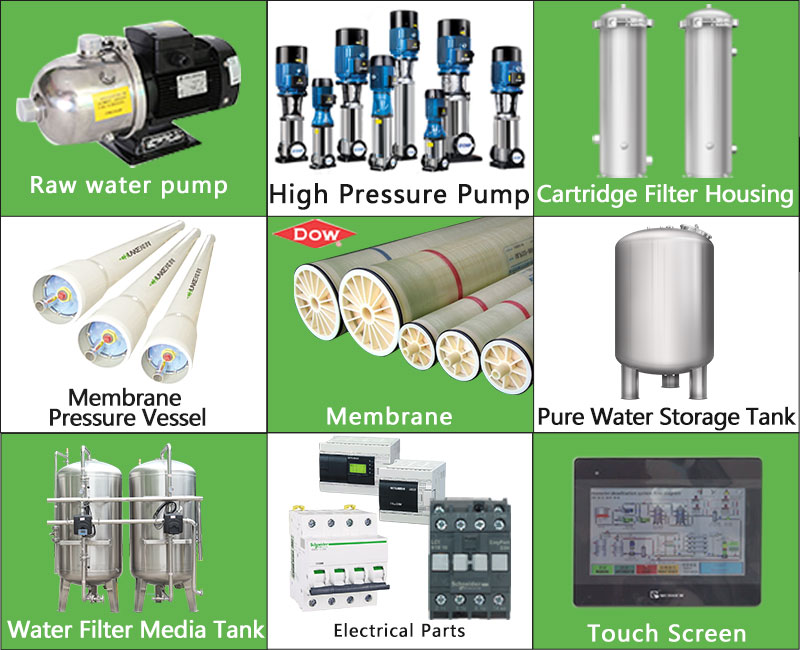

1. Regularly replace the filter element: The pretreatment filter element and reverse osmosis membrane are the core components of the equipment and need to be replaced regularly according to the usage. Generally, the pretreatment filter element needs to be replaced every 6 months, and the reverse osmosis membrane needs to be replaced every 2-3 years.

2. Regularly clean the system: After the reverse osmosis equipment has been running for a period of time, impurities may accumulate on the membrane surface, affecting the treatment efficiency. Regularly cleaning the system can remove dirt on the membrane surface, extend the service life of the membrane, and ensure efficient operation of the equipment.

3. Check the system pressure: System pressure is a key parameter for the normal operation of the reverse osmosis equipment. The pressure of the high-pressure pump and pipeline should be checked regularly to ensure that the equipment is operated within the pressure range designed by the equipment to prevent equipment damage or reduced treatment efficiency due to excessive or low pressure.

Equipment installation and operation precautions for 500 LPH reverse osmosis equipment

When installing and operating reverse osmosis equipment, pay attention to the following points:

1. Installation location selection: Choose a dry and well-ventilated location to install the equipment, avoiding direct sunlight and high temperature environment. There should be enough space around the equipment to facilitate daily maintenance and filter element replacement.

2. Pipeline connection: Ensure that the water inlet pipe, water outlet pipe and sewage pipe are firmly connected and there is no water leakage. Especially for high-pressure pipelines, pressure-resistant pipes must be used and tested multiple times to ensure safety.

3. Operation training: Equipment operators must undergo professional training and be familiar with the various functions and operation steps of the equipment. Especially when replacing filter elements and cleaning systems, they must strictly follow the operating procedures to avoid equipment failures due to improper operation.

Actual case analysis of 500 LPH reverse osmosis equipment

In order to better understand the practical application of 500 LPH reverse osmosis equipment, the following are several typical cases:

Case 1: Medium-sized restaurant

A medium-sized restaurant has a large daily water demand, especially during peak hours when the kitchen and restaurant water consumption surges. After installing the 500 LPH reverse osmosis equipment, the restaurant can stably supply high-quality pure water, which improves the taste of food and customer satisfaction. At the same time, the equipment operates stably and is easy to maintain, effectively reducing the cost of water.

Case 2: Electronics manufacturing plant

An electronics manufacturing plant has extremely high requirements for the purity of cleaning water, and traditional water treatment methods are difficult to meet the requirements. The introduction of 500 LPH reverse osmosis equipment enables cleaning water to meet high purity standards and greatly improve product quality. At the same time, the equipment operates efficiently and has low maintenance costs, helping the company improve production efficiency and economic benefits.

Case 3: Farm irrigation

A modern farm is located in a saline-alkali area, and the irrigation water has a high salt content, which affects crop growth. 500 LPH reverse osmosis equipment effectively removes salt and harmful substances from water, provides high-quality irrigation water, improves crop yield and quality, and improves the soil environment.

Conclusion about 500 LPH reverse osmosis equipment

The 500 LPH in the 500 LPH reverse osmosis equipment means that the equipment can process 500 liters of water per hour. This parameter is an important indicator for evaluating the equipment's processing capacity. Reverse osmosis equipment is widely used in household, commercial, industrial and agricultural fields. It can effectively remove impurities and harmful substances in water and provide high-quality pure water.

When consumers purchase and use reverse osmosis equipment, they need to choose the appropriate equipment model and configuration according to actual needs and water quality conditions to ensure efficient operation of the equipment and stable water supply.

Fall 2: Elektronikfertigungsanlage